Production Schedule Optimiser

Powered by Anaplan

Maximise Profits with the optimum application of supply chain resources.

Function

- Supply Chain

Industry

- Consumer Products, Life Sciences & Healthcare, Manufacturing

The Profit& Production Schedule Optimiser provides an illustration of how Anaplan Optimiser functionality can be applied in the supply chain. This application solves one particular problem that is subject to several constraints. In a real-world scenario, Optimiser is likely to solve multiple, interacting problems at once, and we invite you to consider what scenarios you would like to optimise.

In this case, the problem being solved is to optimise the deployment of multiple drying machines, with differing capacities and drying times in the production process. In addition, profit margin needs to be taken into account to deliver maximum profit from the monthly order book, by prioritising orders that deliver the highest margin. Drying machines are the key constraint in this supply scenario.

In this case, the problem being solved is to optimise the deployment of multiple drying machines, with differing capacities and drying times in the production process. In addition, profit margin needs to be taken into account to deliver maximum profit from the monthly order book, by prioritising orders that deliver the highest margin. Drying machines are the key constraint in this supply scenario.

Solution Features

- Datahub provides a single source of data and removes handling of multiple spreadsheet models across these supply chain processes.

- Automated data transfer between order processing and production scheduling ensures the integrity of data.

- Easy to apply and transparent algorithm functions to solve specific problems, taking into account multiple constraints.

- Solves multiple problems per application.

- Workflow controls the process of data movements and supports effective collaboration between sales, production, and order processing teams.

- Calendar view of machine utilisation.

- Production schedule.

- Order fulfillment schedule.

Line Utilisation

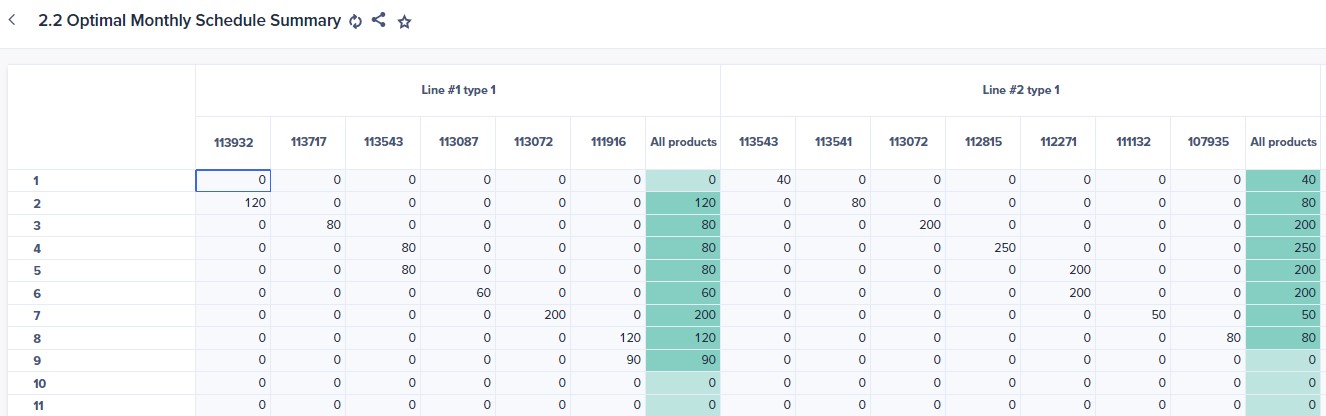

Optimal Monthly Schedule

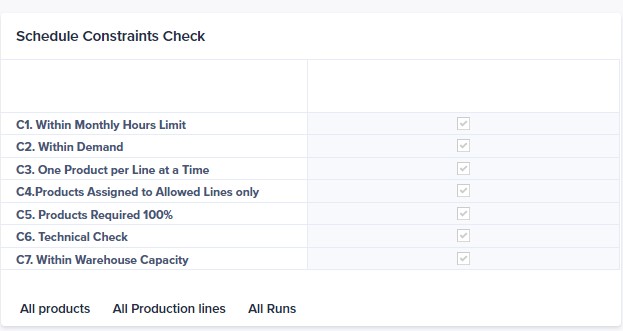

Constraints